Hazardous Area Control System

We were tasked by our client, operating a gas reception station and electrical generation plant, to design and install equipment and instrumentation to provide additional monitoring and safety features. Hardware included additional PLC equipment, junction boxes, cabling, and containment integrated into the existing plant within a short shut down window.

The new loops were designed to meet a range of criteria. The design had to be fully compatible with the existing DCS and ESD systems, and due to the nature of the site, equipment had to be selected to comply with the ATEX directives.

The installation required a variety of protection methods covering a range of hazardous zones and temperature classifications as indicated by the site area classification documents. The final protection methods employed were Ex d (Flameproof), Ex e (Increased Safety), Ex p (Purged/Pressurised), Ex N c (For equipment containing a hermetically sealed device), Ex ia & Ex ib (Intrinsically Safe).

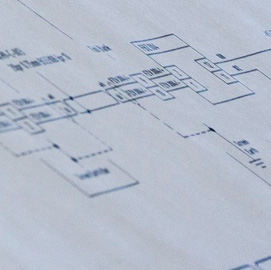

Inspec systems selected, sourced and purchased all of the equipment and provided all of the documentation from the initial design stages for client sign off, through to loop drawings, cable and termination schedules, testing and commissioning during the installation.

The finished system was tested and the initial inspection carried out prior to sign off by ourselves and the client.